13472521719

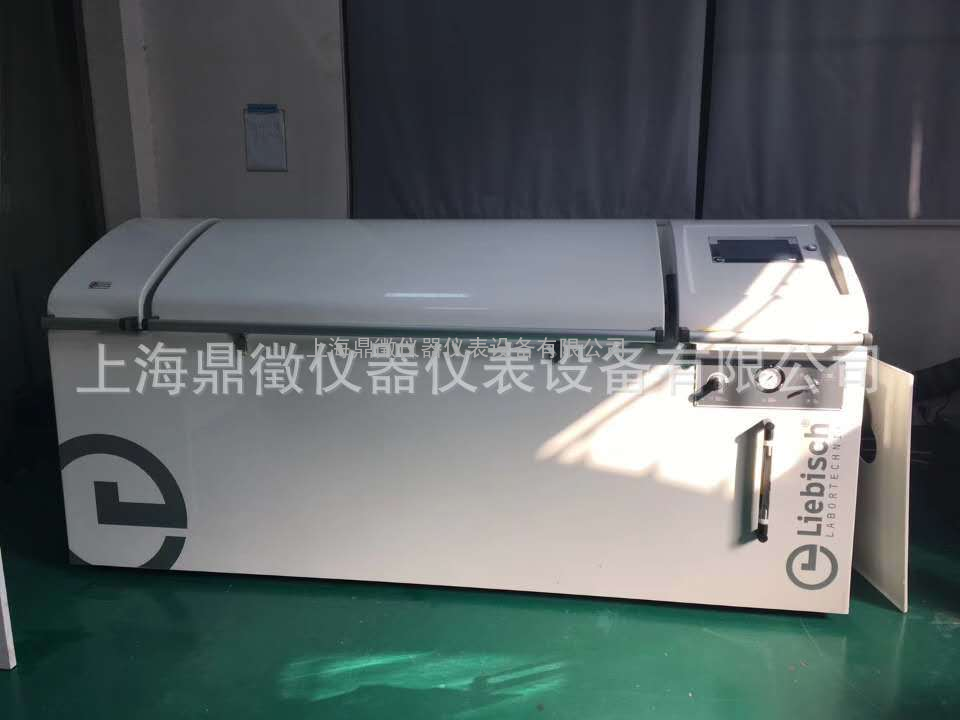

當前位置:上海鼎振儀器設備有限公司>>鹽霧試驗箱>>德國Liebisch>> PV1208海水醋酸腐蝕試驗(SWAAT)

SWAAT即 Sea Water Acetic Acid Test ,中文為循環酸性海水試驗(SWAAT)

本試驗規范描述了評價熱交換器耐腐蝕性的程序(例如冷凝器、蒸發器和水、油和充氣空氣冷卻器)以及其他由鋁合金制成的部件。

Changes

The following changes have been made as compared to Test Specification PV 1208, 1996-01:

Standard restructured

Title changed

Scope expanded

Evaluation intervals changed

Referenced standards updated

1 Scope

This Test Specification describes a procedure for evaluating the corrosion resistance of heat exchangers (e.g., condensers, evaporators and water, oil and charge air coolers), and other components made of aluminum alloys.本試驗規范描述了評價熱交換器耐腐蝕性的程序(例如冷凝器、蒸發器和水、油和充氣空氣冷卻器)以及其他由鋁合金制成的部件。

2 Designation

SWAAT test according to PV 1208

3 Requirement

The components must withstand the required testing without leakage.

The brazed joints, e.g., between flat tube and cooling fin, must have no separations over large areas. Slight selective corrosion of the filler metal is permissible.

Uniform surface erosion and shallow pit corrosion with a low corrosion depth (< 30% of the material thickness) are permitted; however, pitting and other corrosion types such as intercrystalline corrosion on fluid- or gas-bearing parts are not.

The required cycles are to be taken from the Technical Supply Specifications and/or drawings for the individual components.

In principle, the components are inspected with the bright or passivated finish.

The required minimum for complete testing is 5 parts.

組件必須經受住所需的測試而不泄漏。

釬焊接頭,例如扁平管和冷卻翅片之間,必須在大面積上不分離。允許對填料進行輕微的選擇性腐蝕。 均勻的表面侵蝕和低腐蝕深度淺點蝕(<材料厚度30%)是允許的;然而,點蝕等腐蝕類型如晶間腐蝕流體或氣體軸承零件不。所需的周期是從技術供應規格和/或圖紙的各個組成部分。 原則上,這些部件經過光亮或鈍化處理。 完成測試所需*低限度是5個部分。

4 Testing

4.1 Procedure

The procedure is an accelerated corrosion test with a cyclically sprayed aqueous acetic acid sodium chloride solution as the corrosive medium. It is known as the “Sea Water Acetic Acid Test”. The test is carried out in a test chamber according to DIN 50021 on finished parts and evaluated under a microscope using transverse metallographic microsections. The heat exchangers are subsequently tested for leak tightness. The corrosion load occurs in principle from the outside. A simultaneous pressure load is not performed during the test.該程序是用循環噴射的醋酸氯化鈉溶液作為腐蝕介質進行加速腐蝕試驗。它被稱為“海水醋酸試驗”。進行測試,在試驗室根據DIN 50021對成品進行顯微鏡下采用橫向金相磨片。隨后對換熱器進行了氣密性試驗。腐蝕負荷在原則上是從外部產生的。試驗期間不執行同步壓力負荷。

4.2 Leak tightness test

Prior to the corrosion test, the components must be tested for leak tightness. All open connections must be sealed prior to the corrosion test (e.g., using rubber plugs or plastic caps).在進行腐蝕試驗之前,必須對部件進行氣密性試驗。所有打開的連接必須在腐蝕試驗之前密封(例如,使用橡膠塞或塑料蓋)。

4.3 Test solution

The test solution is made from analytically pure table salt (NaCI, purity grade according to German Pharmacopoeia DAB 7), de-ionized or distilled water and acetic acid (purity grade according to DAB 7). For preparation, 42 g NaCI and 10 ml anhydrous acetic acid per liter of solution are used. The pH level of the solution is adjusted with NaOH (purity grade according to DAB 7) so that both the spray solution and the collected condensate have a pH level of 2.8 to 3.0. The measurement is performed electrometrically at (25 ± 2) °C with a glass electrode.測試溶液是由分析純食鹽(NaCI,純度等級根據德國藥典DAB 7)、去離子水或蒸餾水和乙酸(純度等級根據DAB 7)。制備、NaCI 42克和10毫升無水乙酸每升溶液中使用。溶液的pH值用NaOH(根據DAB 7的純度分級)調節,使噴霧溶液和收集的冷凝液的pH值為2.8至3。進行測量電勢滴定來在(25±2)°C用玻璃電***。

4.1 Test temperature

During the test, the temperature in the usable space of the closed test chamber must be (50 ± 1) °C.在試驗期間,密閉試驗箱可用空間的溫度必須為(50±1)°C。

4.2 Test cycle

During a test cycle, the test solution is sprayed for 30 min and subsequently not sprayed for

90 min. If no test fluid is being sprayed, the floor of the test chamber must be completely covered with water. This test cycle is repeated 12 times per day.在測試周期內,將試液噴灑30分鐘,然后不噴涂。 90分鐘。如果沒有測試流體被噴涂,測試室的地板必須*被水覆蓋。這個測試周期每天重復12次。

4.3 Positioning the components in the test chamber

The parts are placed in the test chambers in as-installed position (similar to operating condition). If the components are placed vertically in the vehicle, they shall be set tilted 70° to 80° from the horizontal during the test.各部件作為安裝位置放置在試驗箱中(類似于操作條件)。如果組件垂直放置在車輛中,則應在測試期間從水平方向傾斜70°到80°。

請輸入賬號

請輸入密碼

請輸驗證碼

以上信息由企業自行提供,信息內容的真實性、準確性和合法性由相關企業負責,智慧城市網對此不承擔任何保證責任。

溫馨提示:為規避購買風險,建議您在購買產品前務必確認供應商資質及產品質量。